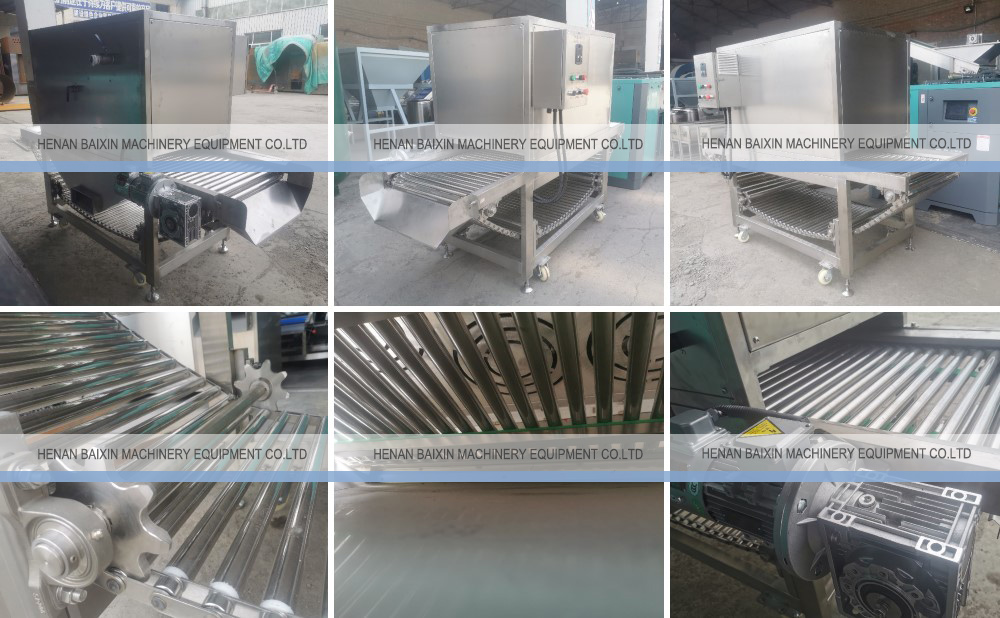

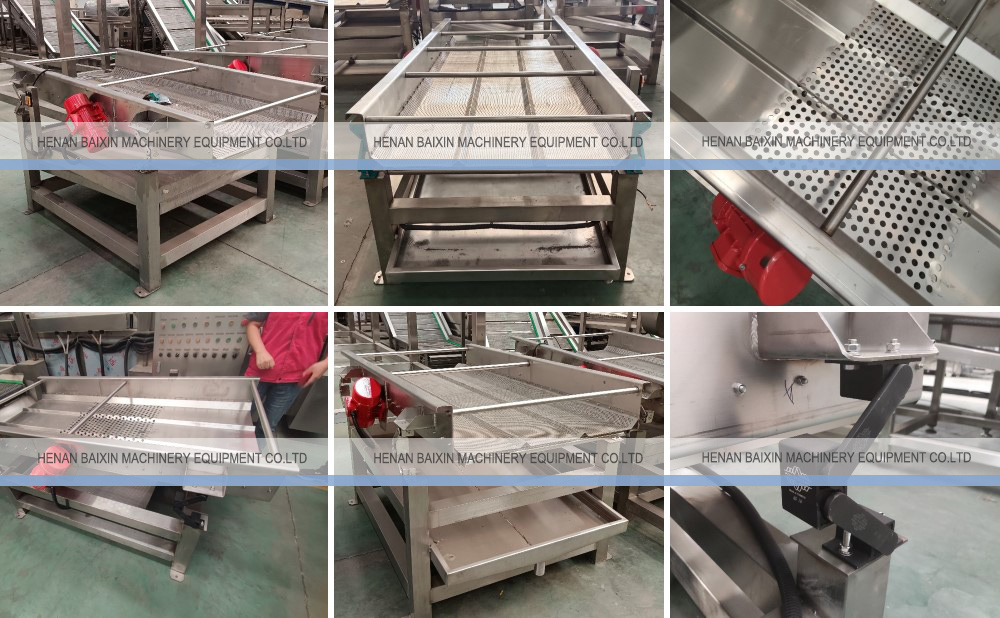

| Equipment | Power | Dimension |

| Onion head and tail remove machine | 0.2kw*2+1.5kw+0.75kw | 2400*1000*1400mm |

| Onion peeling machine | 2.2kw | 3000*900*1600mm |

| Dicing machine | 0.75kw | 745*590*885mm |

| Washing machine | 3.37kw | 3000*1020*1350mm |

| Dewater machine | 0.5kw | 1800*1000*1300mm |

| Drying machine | 21.5kw | 21000*6000*2500mm |

| Onion powder making machine | 15kw | 1040*840*1330mm |

| Packing machine | 6kw | 4000*880*2100mm |

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)